Low NOx Burner

Historically, the quantity of NO and NO2 (NOx) in the products of combustion was not sufficient to affect performance, and their presence was largely ignored. The growing concern with smog and acid rain producing mechanisms (in both of which NOx plays a vital role) have turned the focus around, and low-NOx burner and furnace designs have undergone intense development for the last two decades. Though several remedies have been suggested and implemented, including reburn, staged combustion, preheated fuel, etc., they all try to couteract at least one of the following two basic principles:

- NOx is generated from both air (N2) and fuel components in high temperature, fuel lean environments - so avoid hot spots or intense flames that are coupled with lean zones.

- It is very hard to extract nitrogen originating from the fuel without oxidizing it or forming lots of soot.

Reburn (adding extra fuel at high temperature to reduce the NOx to N2 after a good portion of the main reaction has occurred) addresses the latter problem, but is more of a bandaging fix, and the resulting NOx is still very much dependent on how much comes out of the initial main fire zone.

We have developed a proprietary preheated-fuel burner design that addresses this early NOx formation, and it's features are described below.

Description of Proprietary Technology

- Pre-chamber is inserted between conventional burner and furnace.

- Products of auxiliary natural gas burners are injected in pre-chamber to preheat and devolatilize coal.

- Products of coal devolatilization are mixed with secondary air and burned in the furnace in a conventional manner.

- All subsystems and pre-chamber components are off-the-shelf.

- Technology suitable for power plants and industrial boilers/furnaces.

- Patent pending.

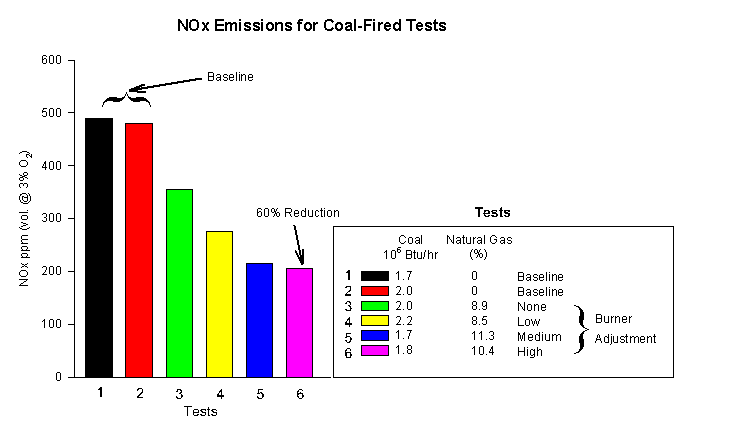

Results from Tests at a 2 MMBtu/hr Pilot Scale Facility

- NOx Emissions for Coal-Fired Tests

- Coal flame stability improved and firing range widened.

- Emission of other pollutants was acceptable.

- Natural gas decreased NOx emission in excess of fuel substitution.

- Burner adjustment further decreased NOx.

- Natural gas (by heating value) decreased NOx by 60% from baseline.

- Level comparable to commercial low-NOx burners.

- Further reduction can be achieved by burner optimization.

- Computational Fluid Dynamics Results using MIFAC