Structural Mechanics

BlazeTech specializes in structural dynamics and failures under a variety of loadings. We have developed fast-running engineering models for these types of problems. We also have many years of experience using commercial software including LS-DYNA, ABAQUS, and CTH to handle cases with more complex geometry and complex loadings. We have also developed our own 3D codes for these problems, such as our improved modification of the Smoothed Particle Hydrodynamics method (SPH) to simulate impact problems.

Tank Failure Due to Pressure Loading

Tank Failure Due to Pressure Loading

Internal Loading

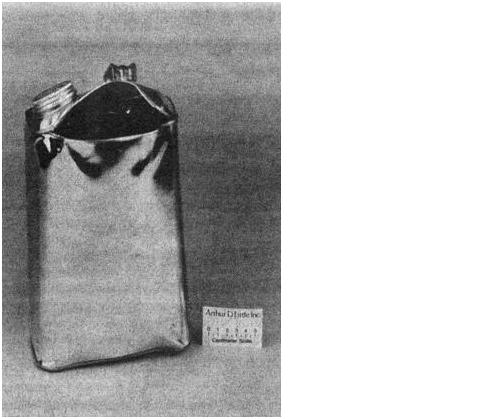

BlazeTech has developed fast-running engineering models to predict failures in tank subjected to internal pressure. Failures occur when the maximum principal stress reaches material strength. In the picture below, failure occurred at the seam.

External Loading

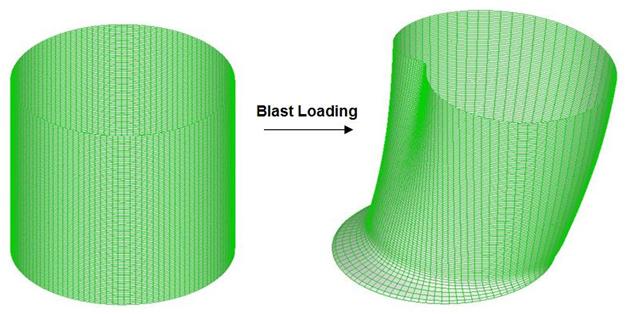

We have developed fast-running engineering models for failures under blast loading of liquid-filled cylindrical containers as found in an industrial facility. The ratio of height to diameter of such containers is of order unity so that a classical bending model does not apply. Our engineering model accounts for inertia, the liquid head, and a non-uniform blast and calculates the deformation, strain, stress, and failure. See sample deformation below for the detonation of a charge placed at the left of the tank center height.

Tank deformation under blast loading

Hydrodynamic Ram

Numerical Simulations of Ram Gun

BlazeTech has been producing numerical simulations of hydrodynamic ram using LS-DYNA software. Click on the image below for a video of the deformation produced by the impact of a projectile (in red) against the front section of a ram gun.

Click the image below to watch a video of the stress contours in the entire ram gun (projectile, impact plate, tube, and support plate.)

Results with Aircraft Structures

Hydrodynamic ram can occur in aircraft structures when sufficiently-energetic debris impact and penetrate a tank below the fuel level, resulting in an increase in pressure that can tear the tank apart. The subsequent fuel release can have catastrophic consequences.

The study on hydrodynamic ram in commercial aviation was basically ignored until the Concorde disaster. Since then, it has received a lot of attention, particularly in Europe.

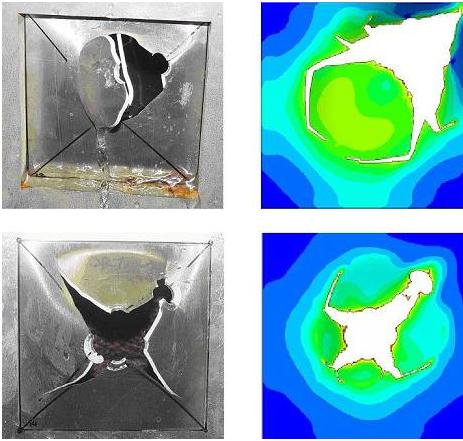

BlazeTech analyzed the response and failure of metal aircraft structural panels subjected to hydrodynamic ram pressure loading. Transient in-plane and out-of-plane displacements of the panels were calculated using COSMOS/M and simplified engineering models. Furthermore, we developed a new method to protect tanks from hydrodynamic ram (link to page). Based on our design, a bread-board system was built and proof of concept tests were carried out. The measured reduction of the hydrodynamic ram effect was very significant.

Description:

- After penetration of fuel tank, fragment motion produces additional loading on the tank wall

- This phenomenon has been observed in tests of fuel tank panels in military applications

Potential Hazards:

- Strong ram:

- Catastrophic rupture of tank

- Loss of fuel and loss of aircraft

- Weak ram:

- Increase in size of penetration hole

- Fuel leakage with potential for a fire

Damage to fuel tank from hydrodynamic ram.

We recently developed a novel system (FuelShieldTM) to protect fuel tanks against ballistically-induced fire and explosions. Preliminary tests demonstrated that the system fully protected a tank that would otherwise rupture catastrophically under identical test conditions. Based on our design, a bread-board system was built and proof of concept tests were carried out. The measured reduction of the hydrodynamic ram effect was very significant.

The system can be used in all types of fixed- and rotary-wing military aircraft as well as certain ground vehicles. Thus, it is of critical value to the Air Force, Navy, Army and their contractors. Also, it has potential safety applications in the chemical and oil/gas industries.

High Speed Impacts

Numerical Simulation

BlazeTech has been developing both dynamic finite element and meshless codes to simulate high speed impact and penetration problems. Click the image below for a video of the impact on a semi-infinite steel plate by a Tungsten projectile, simulated by the Smooth Particle Hydrodynamics method.

Click the image below for a sample video

Testing and Engineering Models

BlazeTech has been conducting several projects to determine damage caused to aerospace structures by high velocity impacts. Impacts can be caused by meteorites or space debris colliding with spacecraft or by ballistic threats against conventional aircraft and weapons. Impacting fragments can hit fuel tanks, engines, electronics, or mechanical components. BlazeTech's models determine overall damage depending on the type of threat and the threat velocity as well as the impacted area of the structure.

Fragment/Pressure Loading

Combined Fragment and Pressure Loading

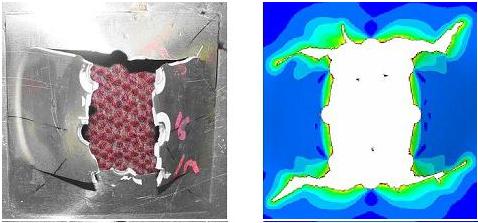

We have been investigating the response of structures to the combined loading of fragments and pressure. Sources of pressure loading include blast, hydrodynamic ram or combustion of vapors inside (say) a fuel tank. Typically the plate is first perforated by fragment impact and then pressure loaded. Under the effect of pressure loading, cracks propagate from the hole enlarging it or even leading to plate rupture. We have characterized this weakening effect of the hole by testing, engineering models and numerical simulation. The effect is expressed in terms of hole enlargement or in terms of the decrease in the pressure pulse required to rupture the plate. Our results relate this effect to the material properties and thickness of the plate, the size, location and number of the holes and the pressure loading. Our results can be used to design more survivable structures and more lethal weapons.

Good agreements are shown below between test results and ABAQUS simulations for the case of one hole, two holes, and three holes in the plate. For the case of a plate with one hole, we also have developed an engineering model that predicts crack length as a function of plate and loading parameters.

One Hole:

Two Holes:

Click the image below for a sample video of the rupture of a plate with two holes:

Three Holes:

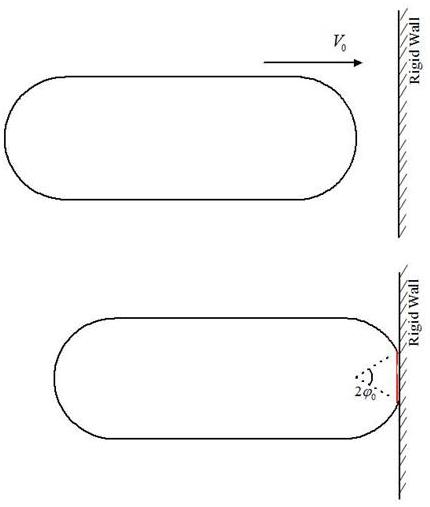

Tanker Impacting a Rigid Wall

When a tanker (trucker, rail, barge, or ship) impacts a rigid wall longitudinally or axially with an initial velocity, it is highly deformed and failures might occur. In BlazeTech's engineering model, the energy method is used to determine its deformation (neglecting bending energy, which is small in a large deformation case). Strain and stress fields and thus failure are predicted from the deformation.

Deformation when impacting a rigid wall